The aviation industry, known for its relentless pursuit of precision and innovation, has embraced automation and robotics to revolutionize aircraft production. The integration of automated systems and robotic technologies has significantly transformed manufacturing processes, elevating precision, accelerating production rates, and enhancing overall efficiency.

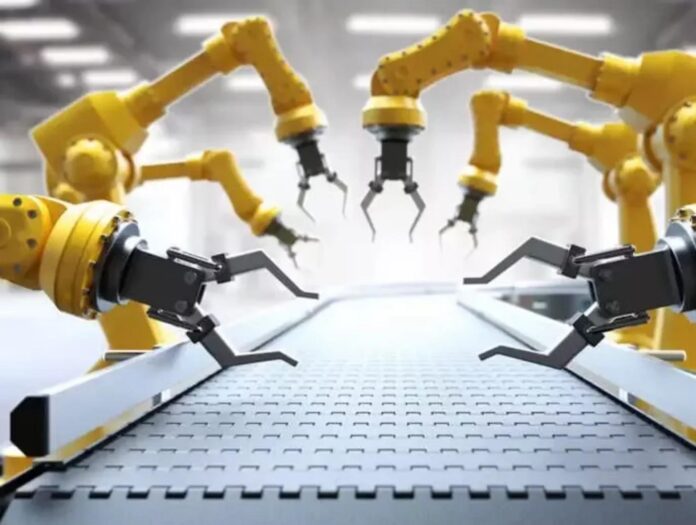

Robotic technology has become a cornerstone of modern aircraft manufacturing. Robotic arms equipped with sophisticated end-effectors perform intricate tasks previously executed by human hands. These versatile machines handle tasks such as drilling, fastening, painting, and quality inspection with unparalleled precision and consistency.

Automated riveting systems represent a significant leap in aircraft manufacturing. Robotic riveting machines precisely and efficiently install thousands of rivets, ensuring uniformity and structural integrity while reducing human error. These systems streamline the assembly process, significantly cutting down production time and enhancing quality control.

Additive manufacturing, often referred to as 3D printing, has emerged as a game-changer in aerospace production. This technology allows for the creation of complex components layer by layer, offering design flexibility and the production of lightweight, high-strength parts. 3D printing enables rapid prototyping and the creation of intricate structures previously unattainable through traditional manufacturing methods.

Unmanned Aerial Vehicles (UAVs) or drones have found applications in aircraft production, particularly in inspections and logistics. Drones equipped with cameras and sensors navigate through manufacturing facilities, conducting inspections of hard-to-reach areas, improving safety, and accelerating assessment processes.

Automation in aircraft assembly lines plays a pivotal role in streamlining workflows and optimizing production. Automated guided vehicles (AGVs) transport components and materials within manufacturing facilities, reducing the need for manual handling and minimizing transportation delays.

Collaborative robots, known as cobots, work alongside human workers, enhancing efficiency and safety in aircraft production. Cobots assist in tasks that require precision or heavy lifting, augmenting human capabilities while ensuring a safer working environment.

Precision in manufacturing is crucial to ensure the structural integrity and performance of aircraft. Robotics enable consistent and accurate assembly, reducing variations and ensuring uniformity across aircraft components. This precision contributes to enhanced safety and reliability in aviation.

The implementation of automation and robotics in aircraft manufacturing significantly reduces human error. Automated systems perform repetitive tasks with high accuracy, minimizing the likelihood of mistakes that could compromise the quality or safety of the aircraft.

Speed is a crucial factor in aircraft production. Automation and robotics accelerate production rates, significantly reducing lead times and time-to-market for new aircraft models. This increased pace of manufacturing ensures timely deliveries and responsiveness to market demands.

The use of automated systems and robotics in aircraft production isn’t without challenges. Initial investment costs, integration complexities, and the need for specialized training are among the hurdles faced by manufacturers. Overcoming these challenges necessitates strategic planning and continuous refinement of automated processes.

Cybersecurity in automated systems is a growing concern in aerospace manufacturing. Ensuring the resilience of automated systems against cyber threats is imperative to safeguard critical production processes and prevent potential disruptions.

The future of automation and robotics in aircraft production holds immense promise. Advancements in artificial intelligence (AI), machine learning, and sensor technologies will further enhance the capabilities of automated systems, enabling adaptive and intelligent manufacturing processes.

Continued research and development in automation and robotics will drive further innovation in aerospace manufacturing. Collaboration between industry leaders, technological innovators, and regulatory bodies will play a crucial role in shaping the future of automated aircraft production.

Automation and robotics have ushered in a new era of precision, speed, and efficiency in aircraft manufacturing. As technology continues to advance, the integration of these cutting-edge systems will continue to redefine the way aircraft are produced, ensuring that the skies remain filled with safer, more efficient, and technologically advanced aircraft.